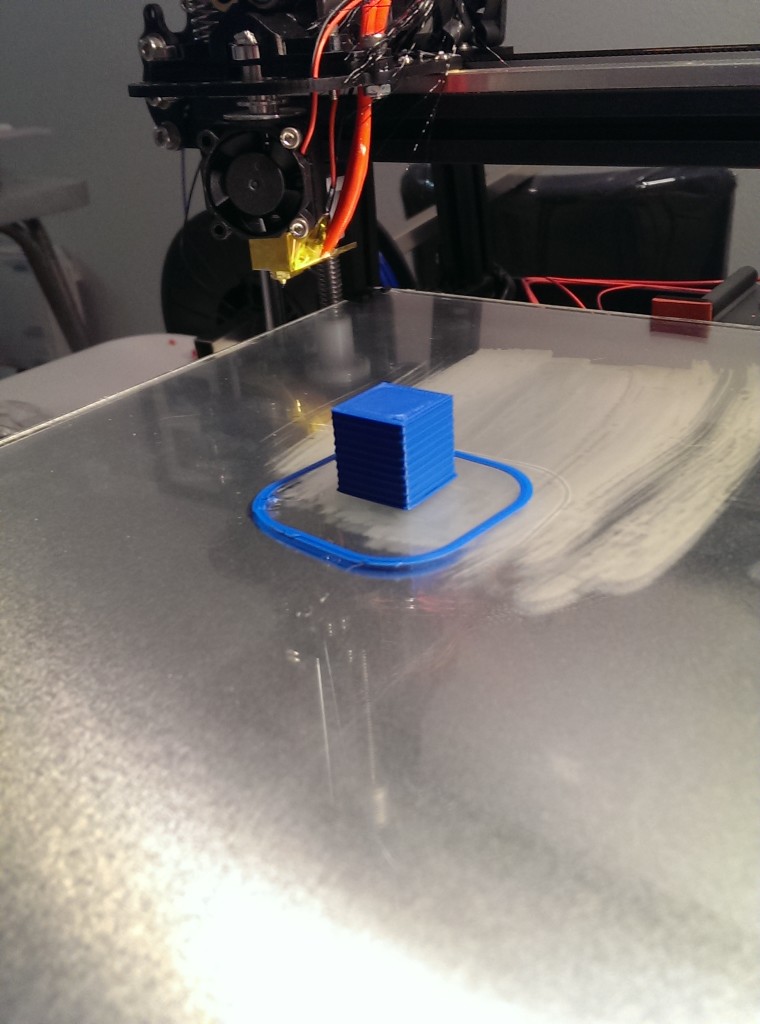

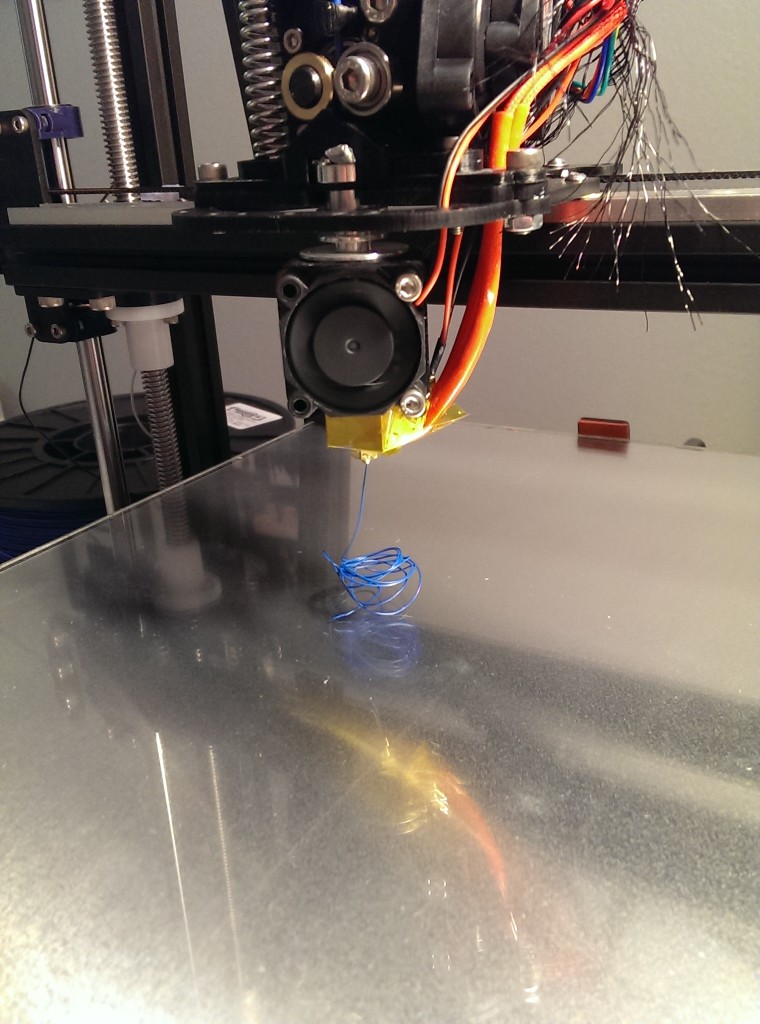

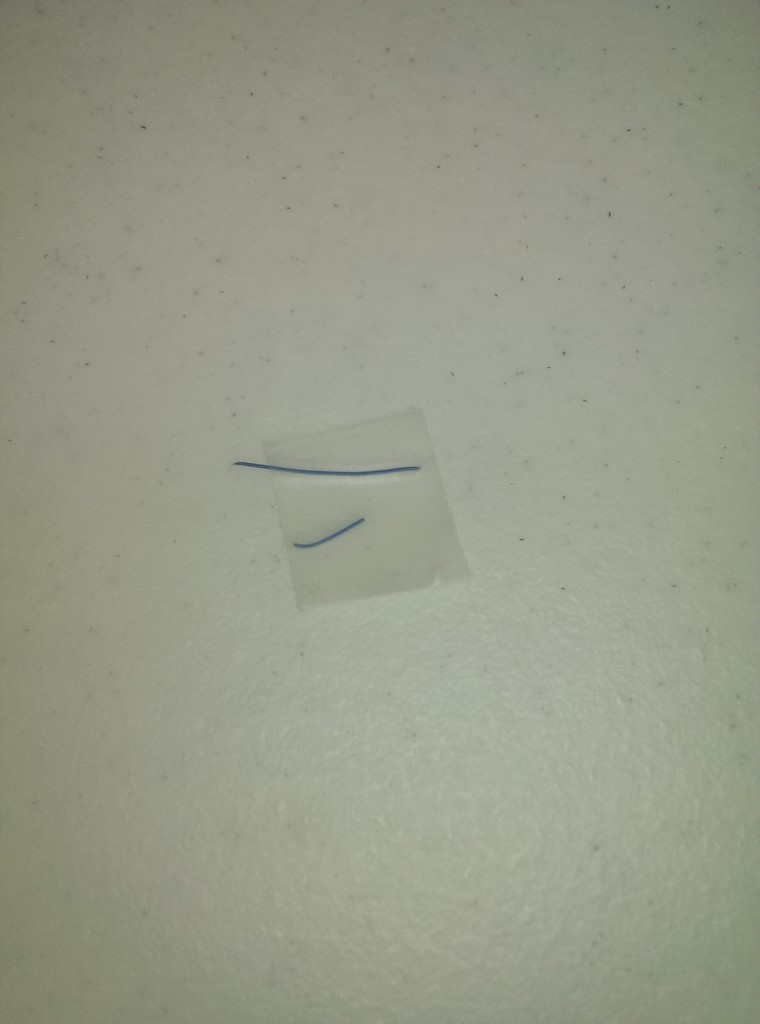

Against all odds my first print was a success (using ABS even):

That’s after everything cooled down a bit, you can faintly see the traces on the bed where the pieces were before they popped loose (due to the bed shrinking as it cooled at a different rate than the plastic) and I moved them. It’s decidedly not a perfect print (horizontal banding, some spots where the perimeter pulled apart between layers, some waviness on one corner where I’m guessing the layer started), but considering the ambient temperature in my living room is 18C I’m surprised I got a successful print on my first try.

Interestingly, the quality of this piece is actually good enough for the first couple things I was planning to print so I may do some printing before I dive into further calibration.

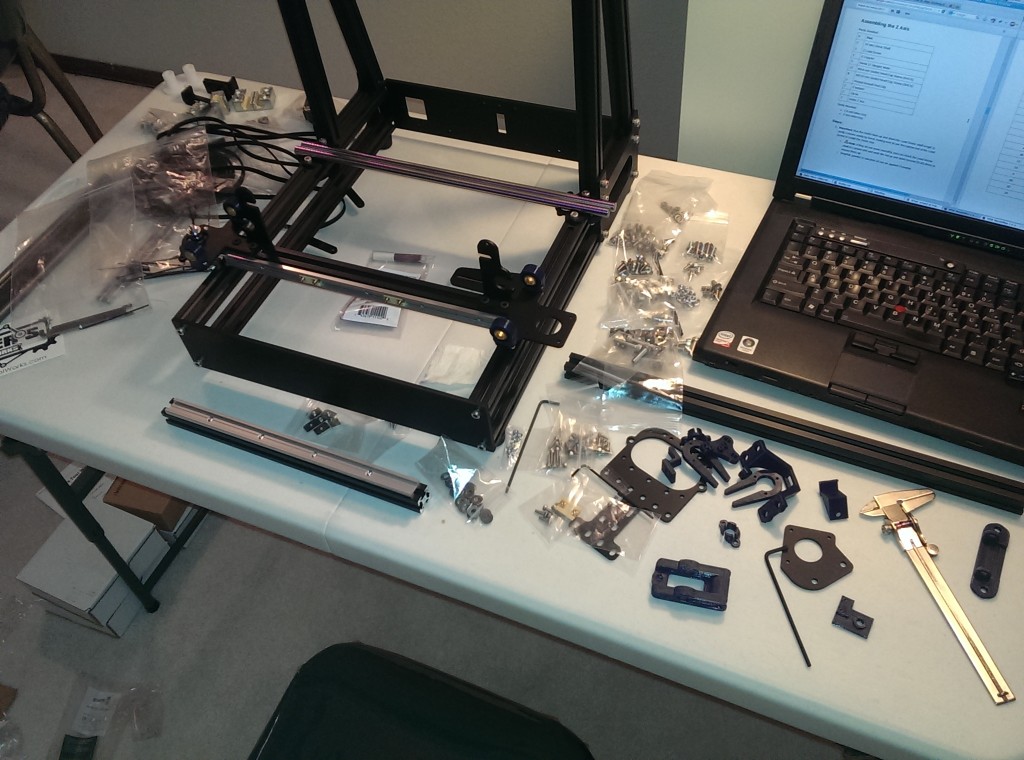

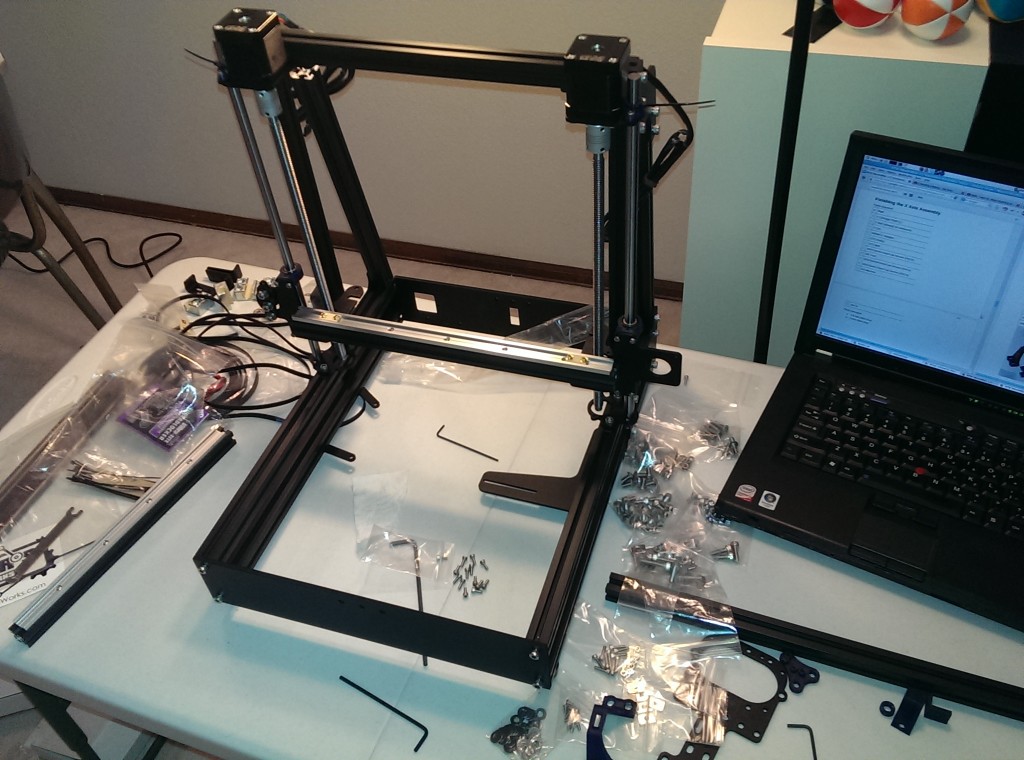

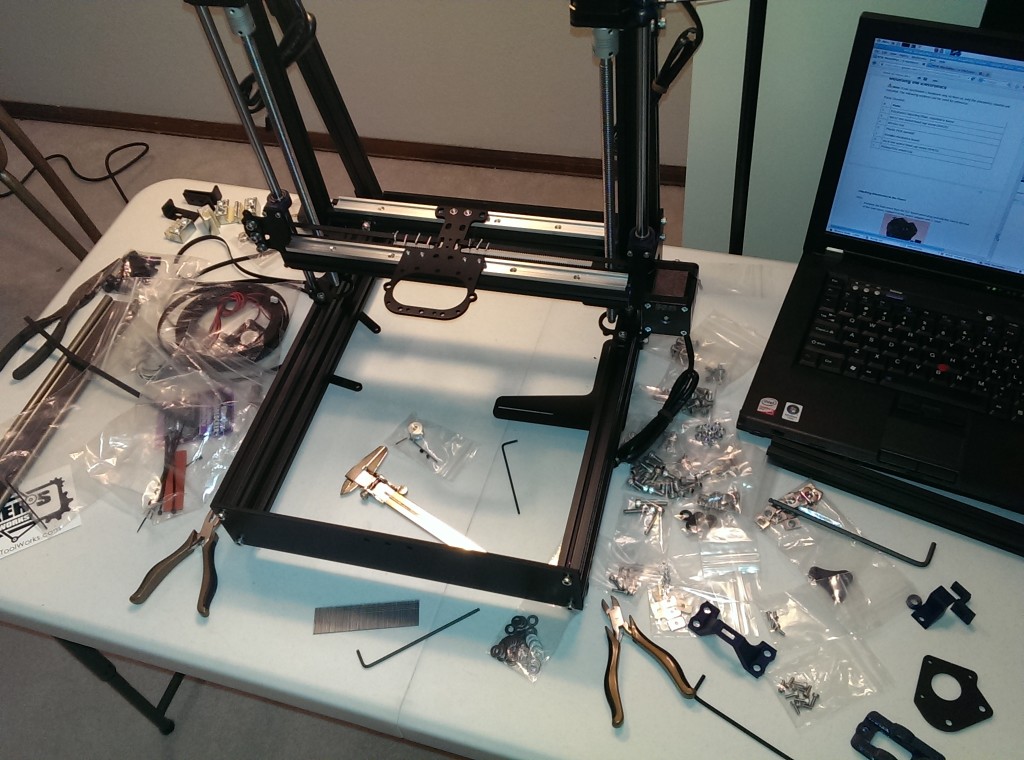

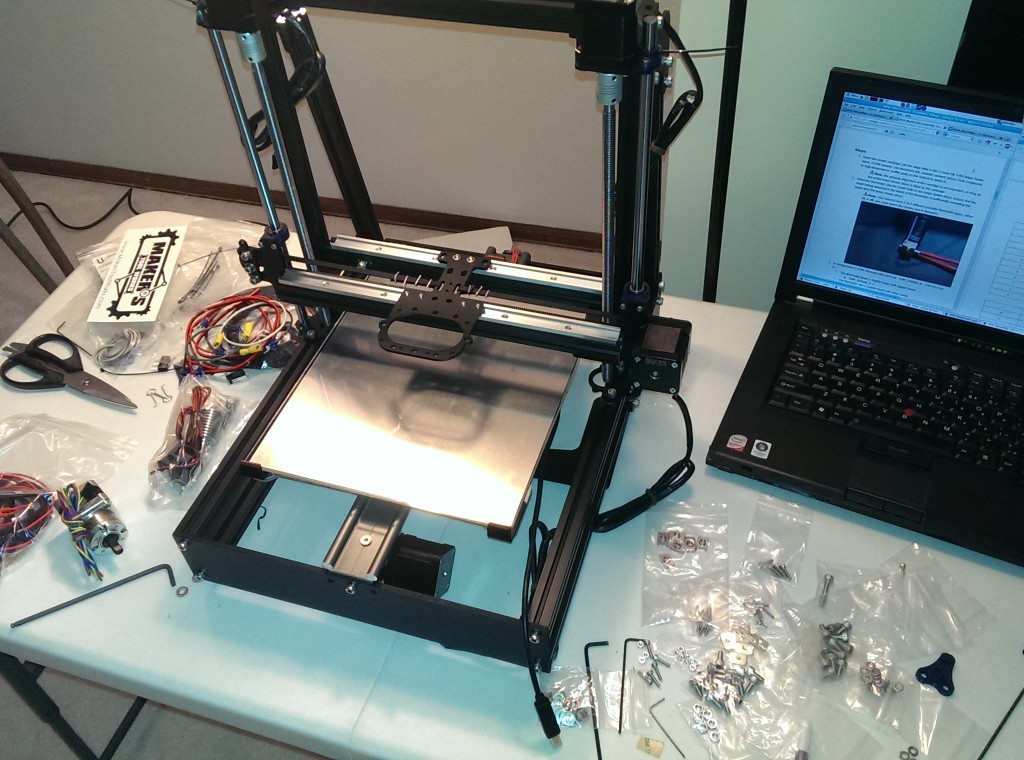

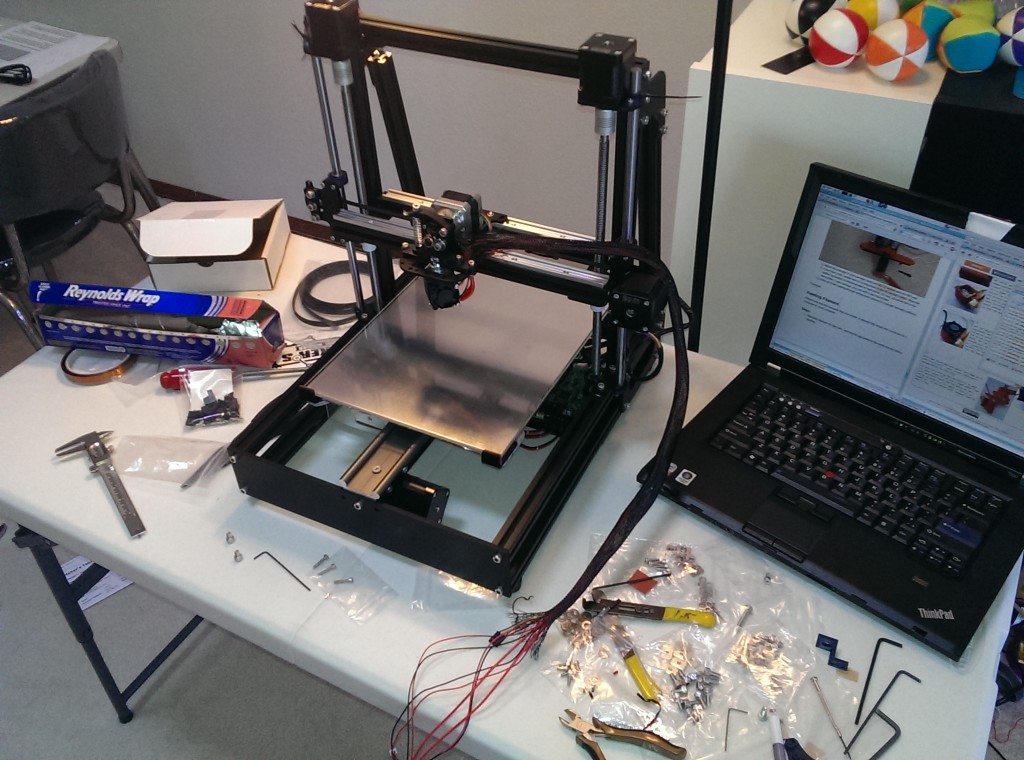

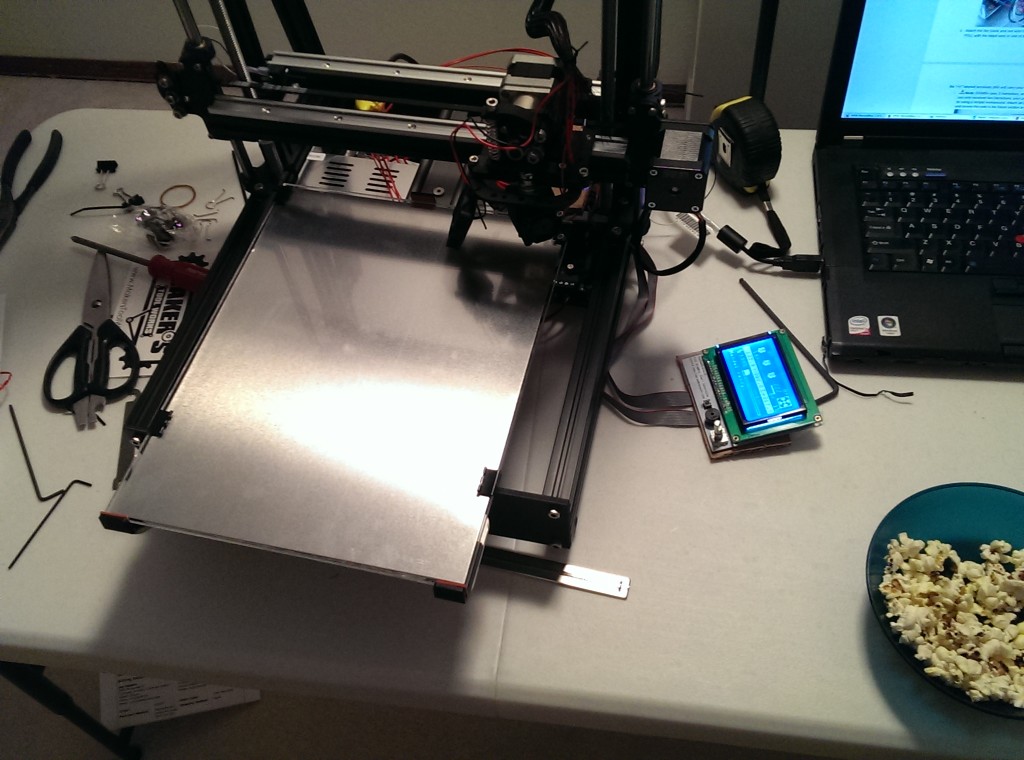

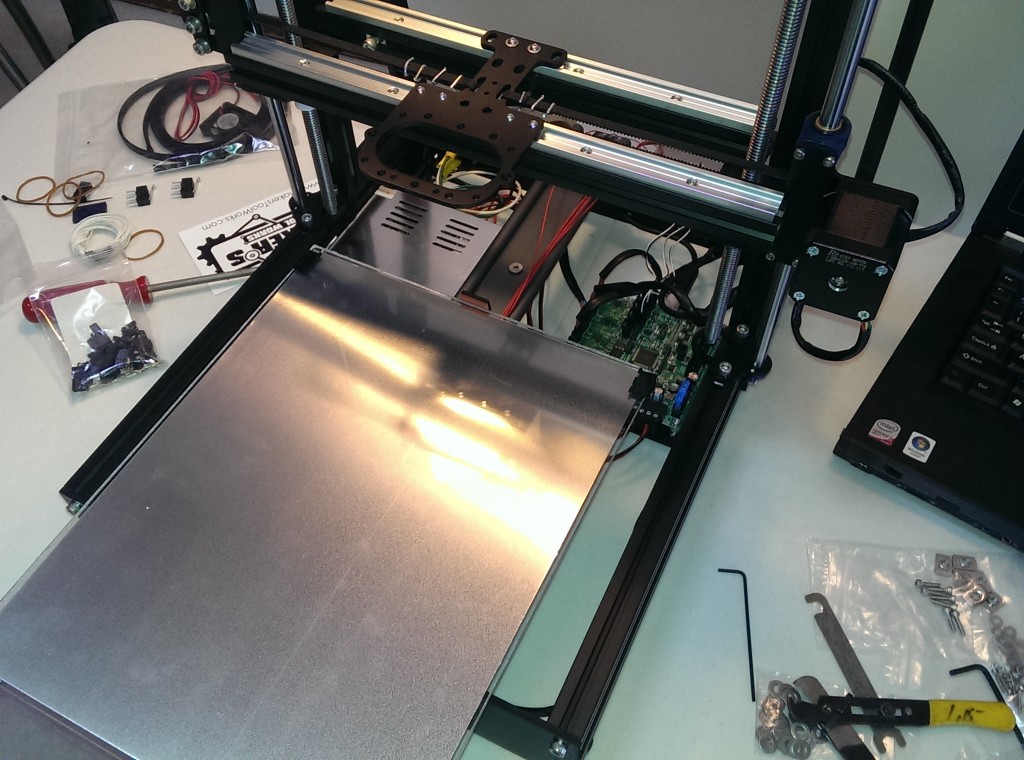

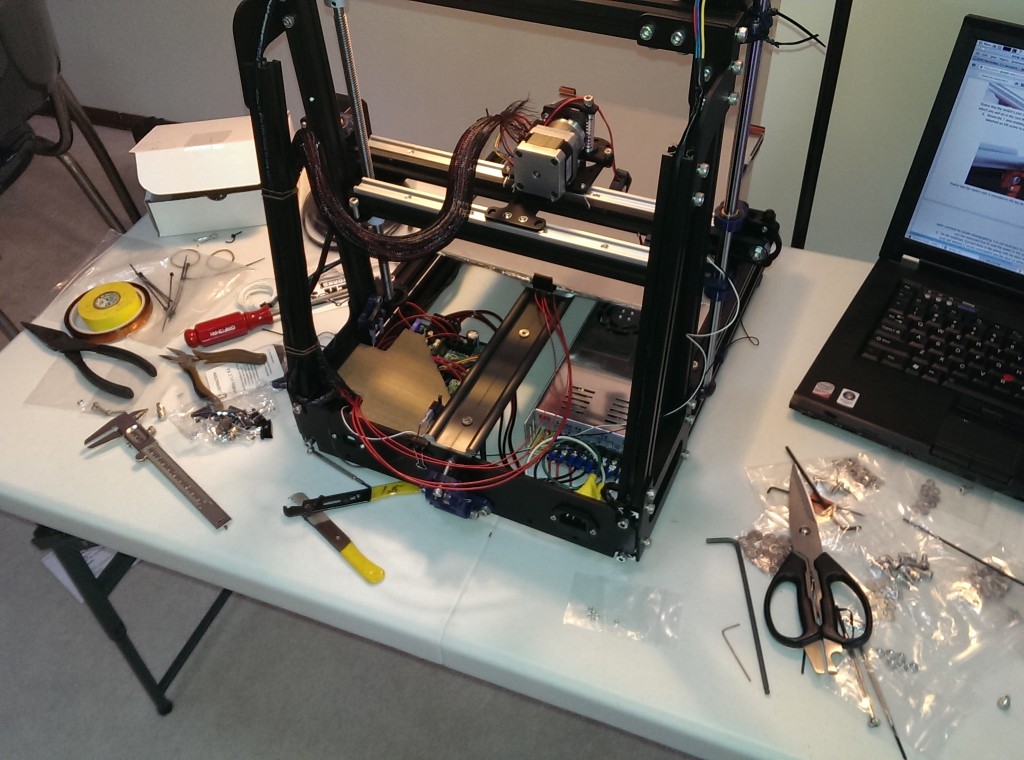

As promised, here are pictures of the build process:

Entire kit laid out on my project table.

Upright frame assembled/installed

Electronics installed (but not wired)

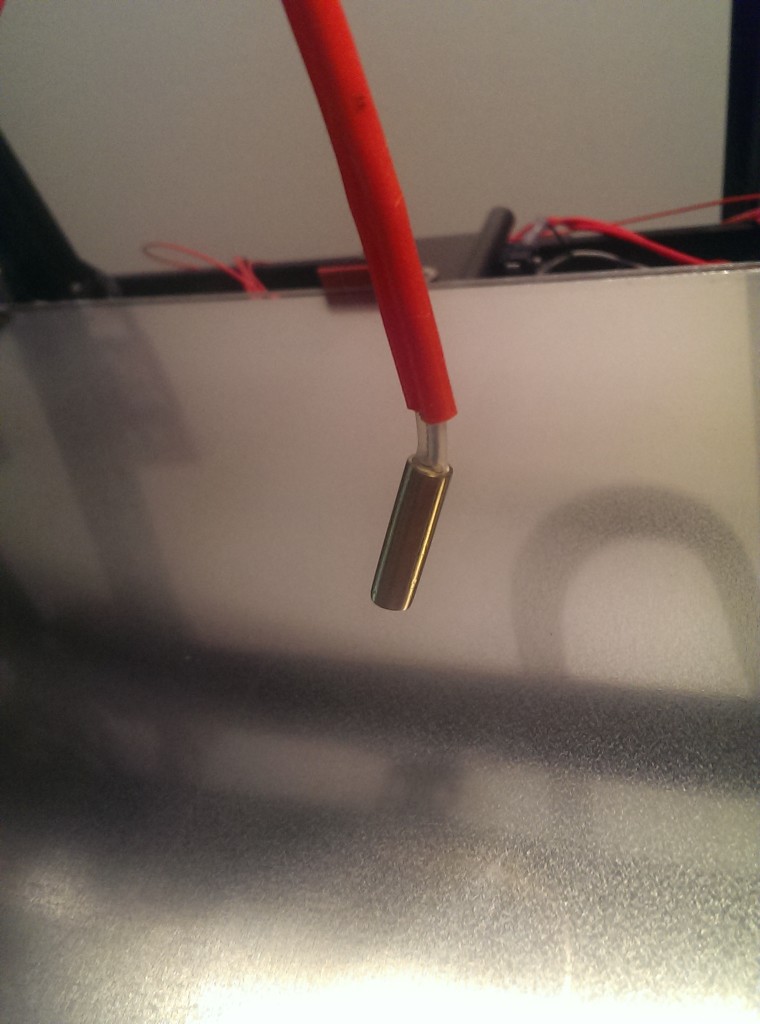

Wiring complete (including endstops)

Bonus/reward for scrolling this far, video of my first print:

Infill layers

More infill