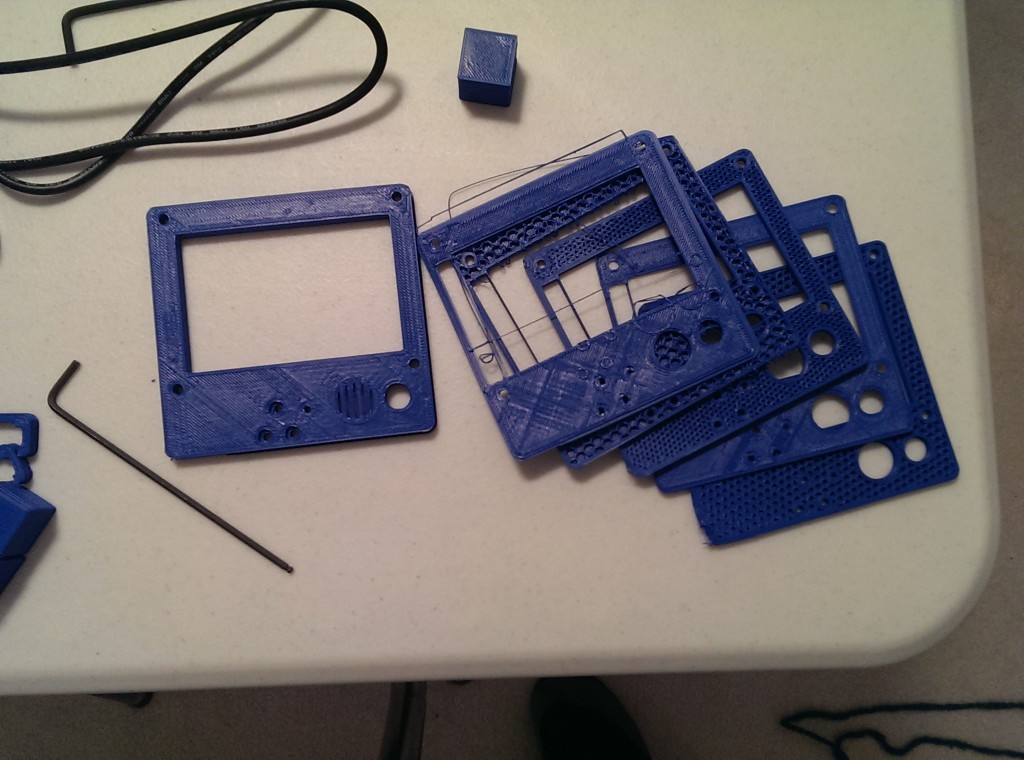

I spent most of today trying to figure out how to get large prints in ABS to complete without curling up in the corners and ruining the print. Here’s the stack of LCD faceplate attempts that I produced.

The first attempt used the same settings as the calibration cube, but after about an hour it had curled enough in two corners that it was clear it wasn’t going to complete in a useful state. The second through fourth prints were attempts to print with the printer set to faster speeds to see if it would be able to keep ahead of the curl. Turned out no, and I had to bump the temperature up by a good bit to keep it from randomly jamming because it was trying to push plastic through the nozzle at about the same speed that the plastic was melting. The last prints I started playing with infill settings – it’s not a structural piece so the default of .4 infill is probably way overkill. I also had to slow down the travel time because it skipped steps a couple times.

The successful print was with .1 infill, a 1 mm brim, and the travel speed limited to 200 mm/s (down from a high of 500 mm/s). It still took over half an hour to print and there was slight curling in one corner (I’ll try increasing the brim next time to see if that’s actually what was helping). I think I’m going to need a proper heated chamber to print large pieces of ABS (luckily most of what I want to do in ABS is small pieces), so I might start trying to work with PLA tomorrow even though it’s not recommended for the E3d hotend I have.

The banding I was getting last night turned out to be from one of the threaded rods being bent. The design prevents it from pushing the extruder back and forth so I didn’t expect it to be a problem, but as it turned it was raising/lowering the end of the X-axis from where it should have been. I don’t think I quite have it perfect yet, but it’s much better. I also smoothed out the motion of the Z-axis while I had the rods removed so now I shouldn’t have any binding.

Also, because I recorded it, here’s a video of a short print from start to finish: